Air fryers have quickly gained popularity as a convenient and fast way to evenly cook crispy food. With the hype also comes a multitude of options, sizes, and features to choose from. At RTINGS.com, we developed a robust set of tests to help determine which air fryers perform best in their key areas: speed and frying quality. For those looking to do more than air fry, we also assessed their versatility in modes like baking and broiling. We tested 20 popular models and found that larger capacity models consistently outperform their smaller counterparts—even if you aren't cooking for a crowd.

You Can Track Your Cooking Progress If You Have A Scale

Depending on the food you want to cook, you'll typically refer to the instructions on the package or the manufacturer's recipe in the product manual. But these are only recommendations—they aren't consistent enough to reliably measure performance across a variety of different air fryers and food types. To standardize our testing, we had to find a metric that was easily repeatable across a wide variety of products and could focus on the most appealing aspects of air fryers: speed and even crispiness.

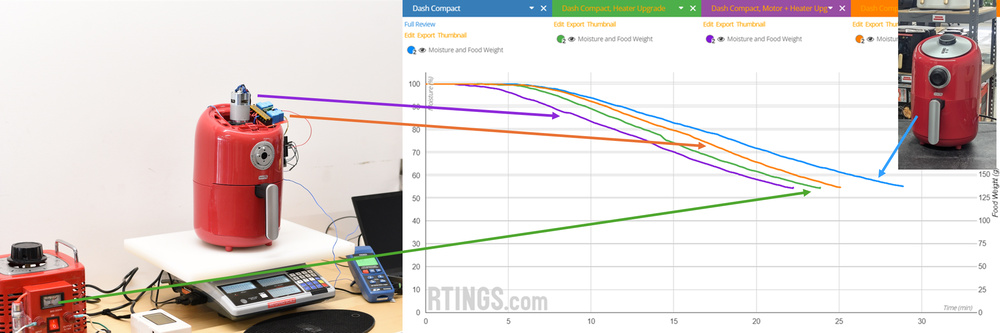

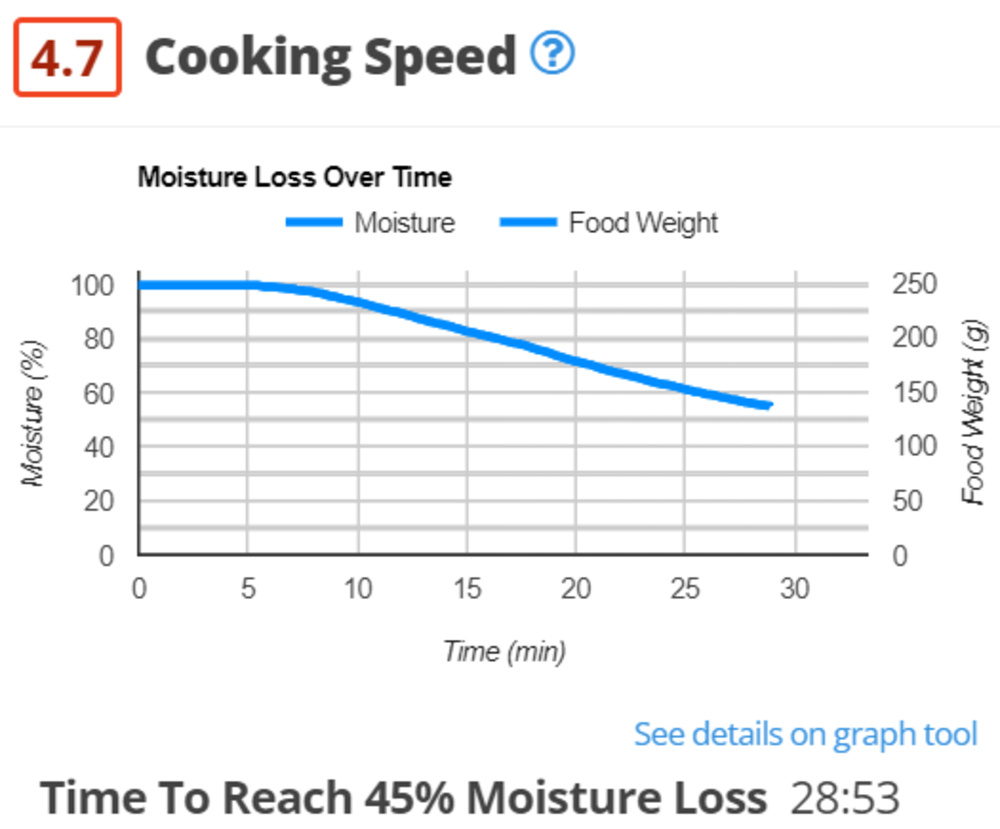

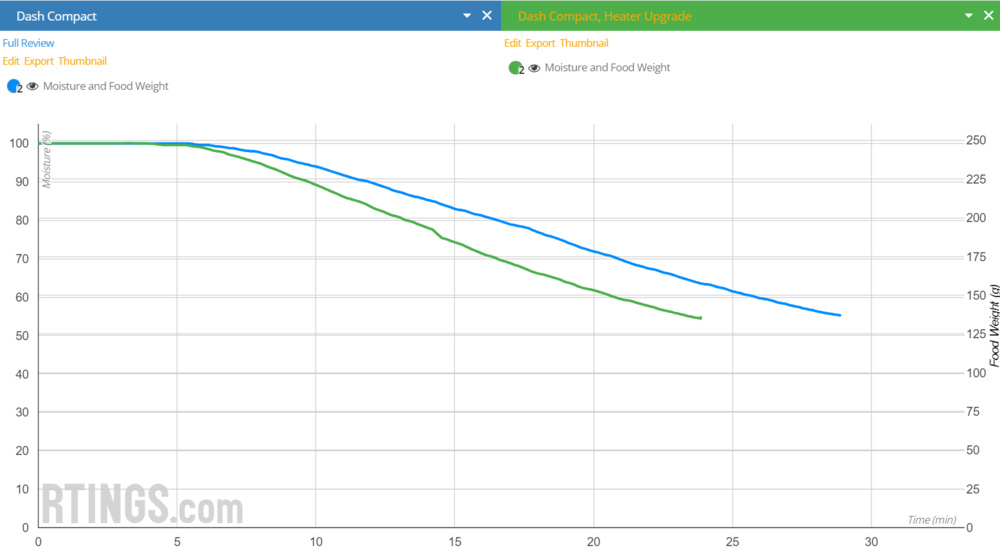

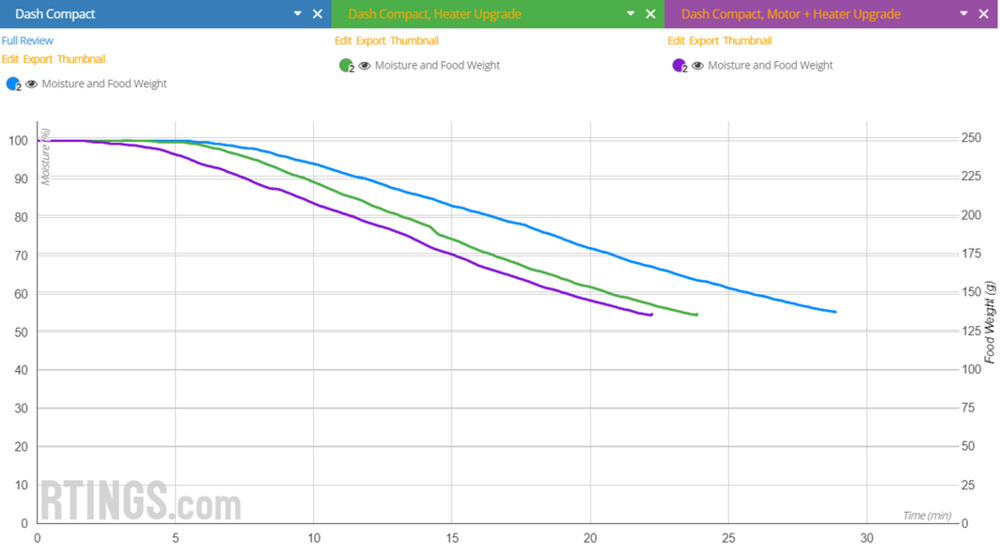

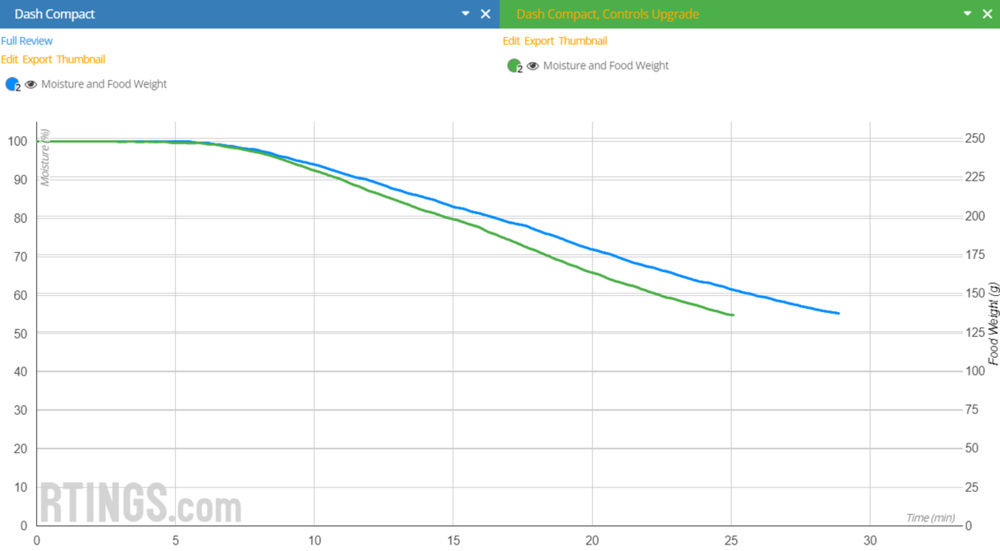

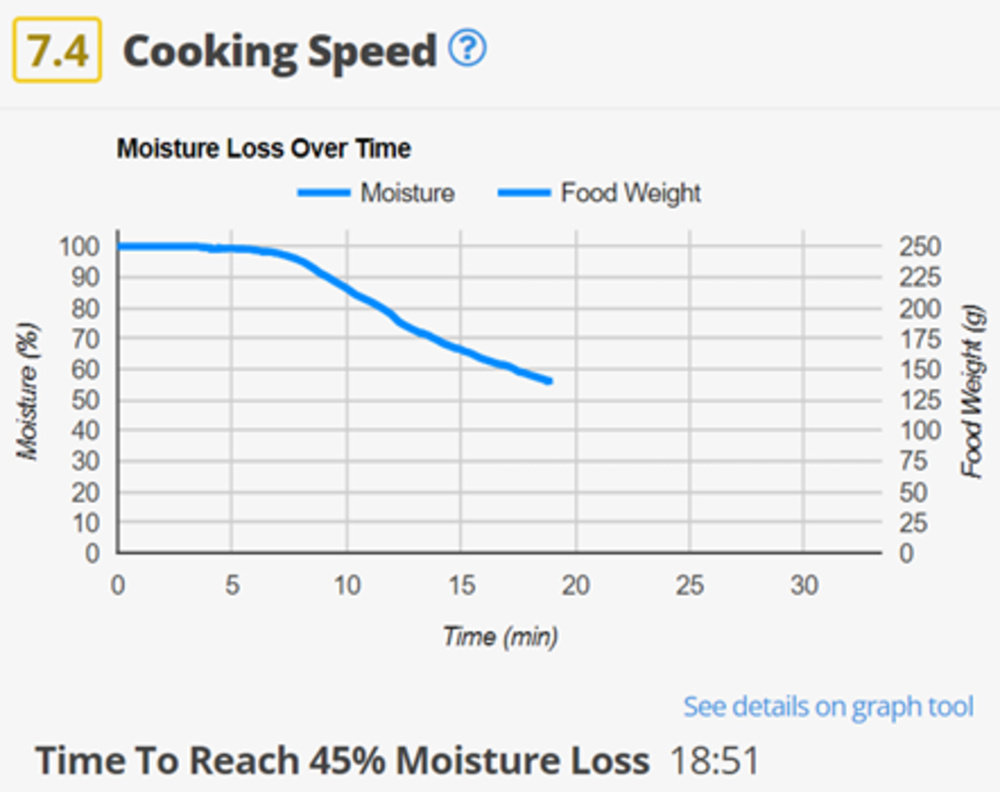

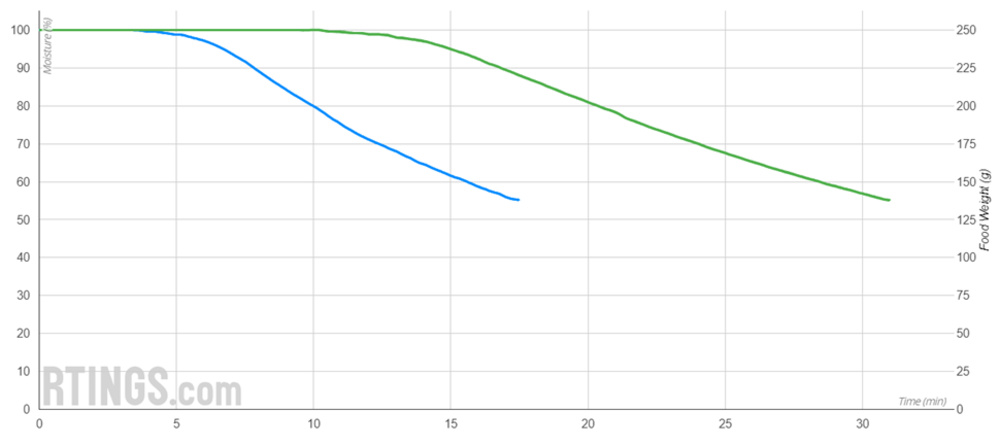

That metric was moisture loss. As most food cooks, it releases moisture. Think of when you're cooking a burger and see how much it's shrunk when it's done cooking. By placing our air fryers on a digital scale, we observed the scale reading rapidly decrease as the food cooked. We could determine a target moisture loss percentage for a given food type that correlates to an ideal cooking result. For example, with frozen chicken wings, we found that a 30% loss in moisture resulted in a crispy wing while maintaining its juicy interior. For frozen French fries, a 45% loss in moisture resulted in the ideal balance between crispiness and fluffiness. Using this test method and a standardized cooking temperature, our fastest air fryers reached this target in as little as under 16 minutes, with our slowest model taking an agonizing 29 minutes to achieve the same moisture loss target.

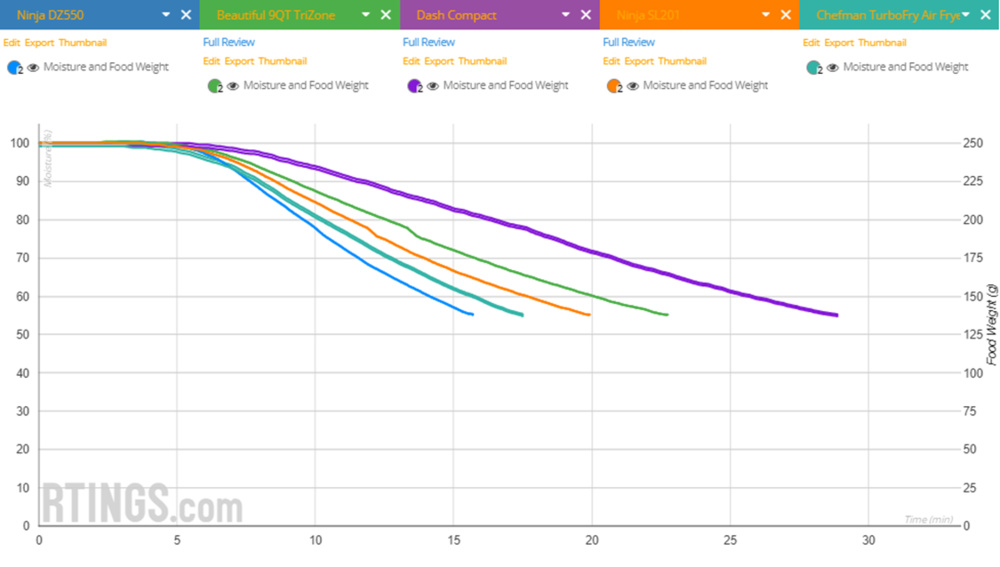

Above, you can see the comparisons of moisture loss over time representing the cooking speed of five air fryers we tested.

French Fries Are The Perfect Test Food

Aside from cooking speed, another major draw for air fryers is their ability to create evenly cooked, crispy food. Quantifying this required the right type of test food. We tried dozens of foods, from conventional air-fried choices like frozen chicken nuggets and wings to more obscure picks like Texas toast and croissants. The ideal food, however, was the first you'd think of for air frying: frozen French fries.

Store-bought frozen French fries are consistent in shape, size, and weight, making them easy to standardize. Because there are many in a batch, it's possible to measure differences in cooking evenness from fry to fry. Their shape also makes crispiness easy to assess with a simple snap test.

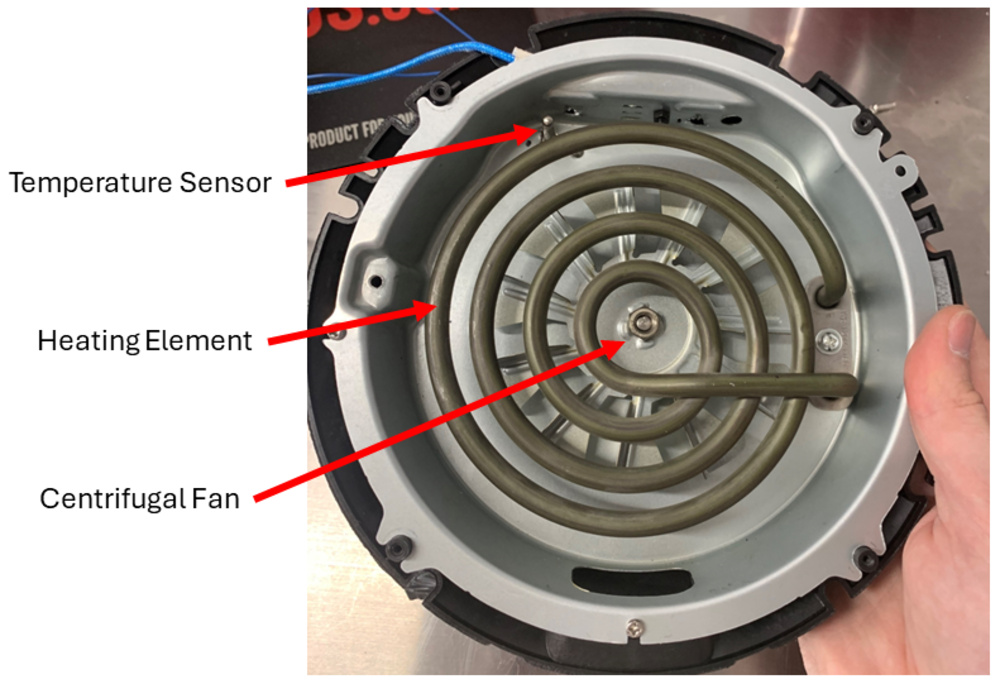

Optimizing Heat Transfer

Air fryers consist of three main elements for cooking: a heating element, a centrifugal fan, and a temperature sensor. The fan circulates air through the heating element, heating it before directing it to the food to transfer heat. The air and moisture removed from the food are then exhausted to the environment. The temperature sensor ensures the air fryer maintains the set temperature throughout cooking.

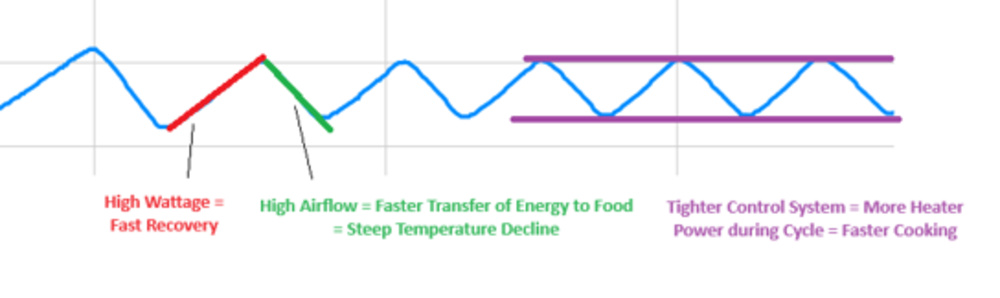

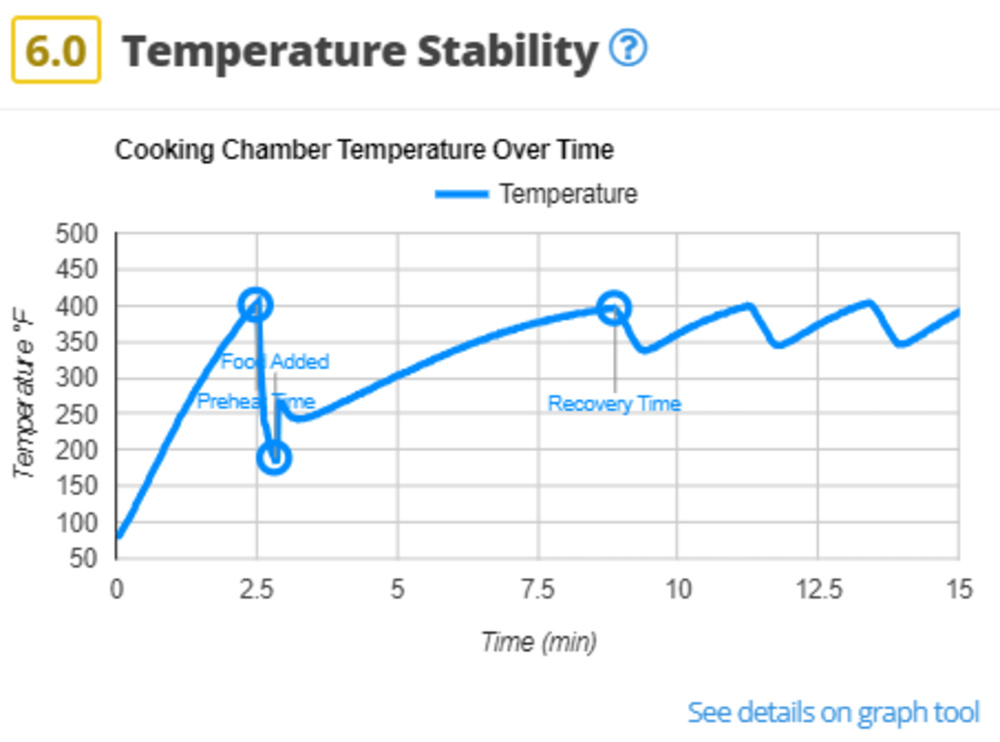

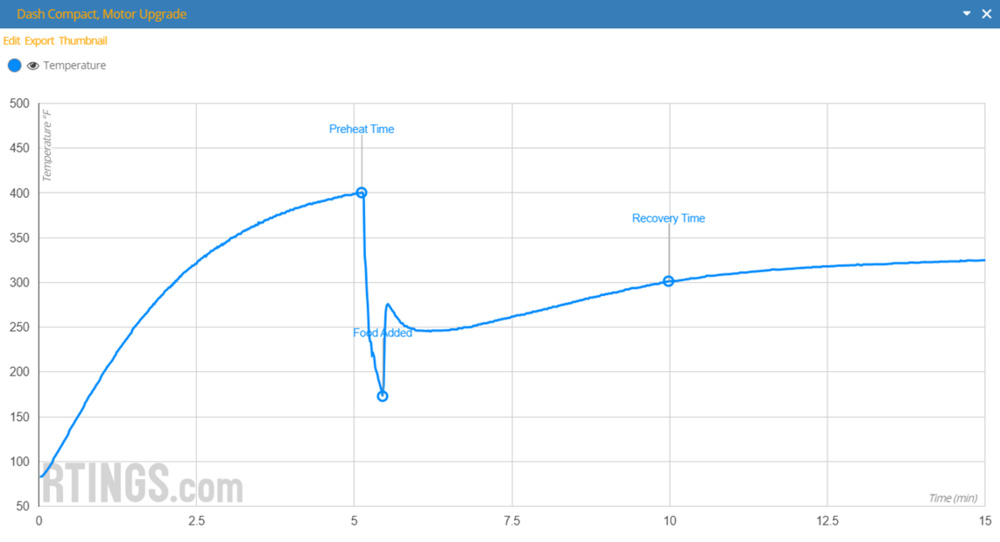

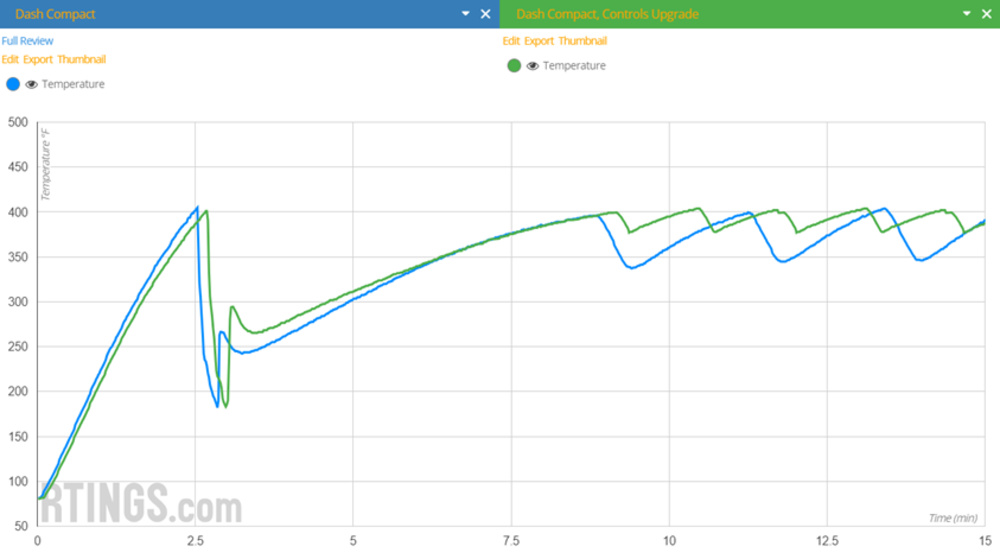

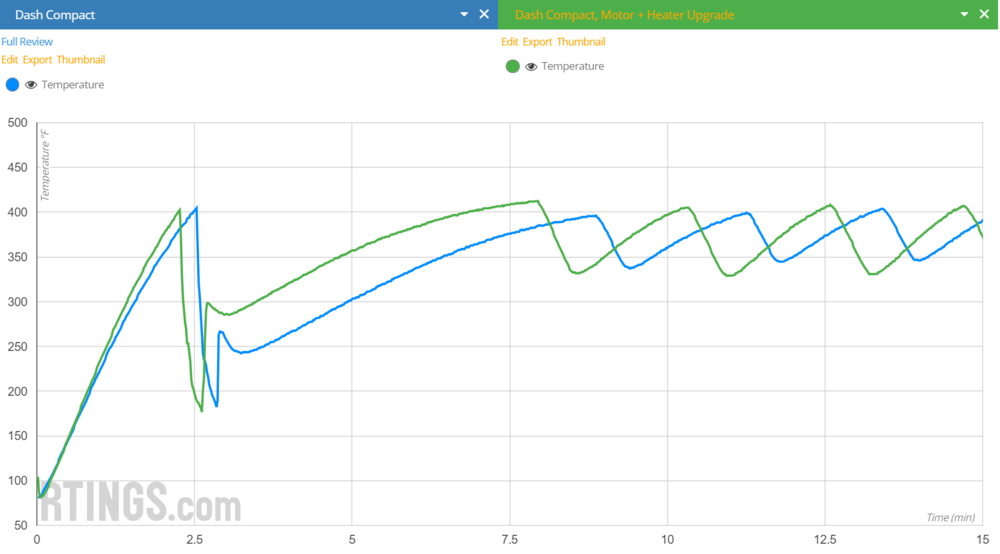

The graph below displays cooking chamber temperature over time and depicts the impact of each element:

Our worst-performing air fryer in almost every test was the Dash Compact, a compact model with a small capacity of 2 quarts (1.89 liters). While not the fastest, the motor speed is a respectable 2900 RPM. The heating element is rated for 1000 watts, which is on the low end, although not uncommon for air fryers of this size. However, the Dash gets hit the hardest in its wildly unstable temperature control system, showing temperature fluctuations as high as 59 °F from the set point. You can see the combination of these parameters in its temperature stability curve:

Due to its small size, the Dash Compact has a fast preheat time of 2.5 minutes. However, once you add food, its low wattage leads to a long temperature recovery time, which ultimately results in a very long cooking time of 28:53:

To explore how each element affects performance, we prototyped a supercharged version of the Dash, allowing us to vary the wattage, motor speed, and temperature control.

High Wattage, Fast Recovery

Air fryers typically incorporate a tubular-style, resistive heating element in a spiral shape, similar to elements seen on older electric stovetops. In air fryers, these elements can range from as low as 800 watts to as high as 1800 watts in larger models (in North America, effectively maxing out a standard 15-amp residential breaker).

Heater wattage dictates how much energy is available to transfer to the food and how quickly an air fryer recovers lost heat when cooking. Higher-wattage elements recover faster, maintaining a steady heat delivery to the food. In contrast, lower wattage elements, often found in 2-4 quart (1.89-3.79 liters) air fryers, struggle to maintain their temperature, limiting the energy available for cooking and leading to slow cooking times. For our prototype, we sourced a higher-rated heating element of 1300 watts despite being the same size:

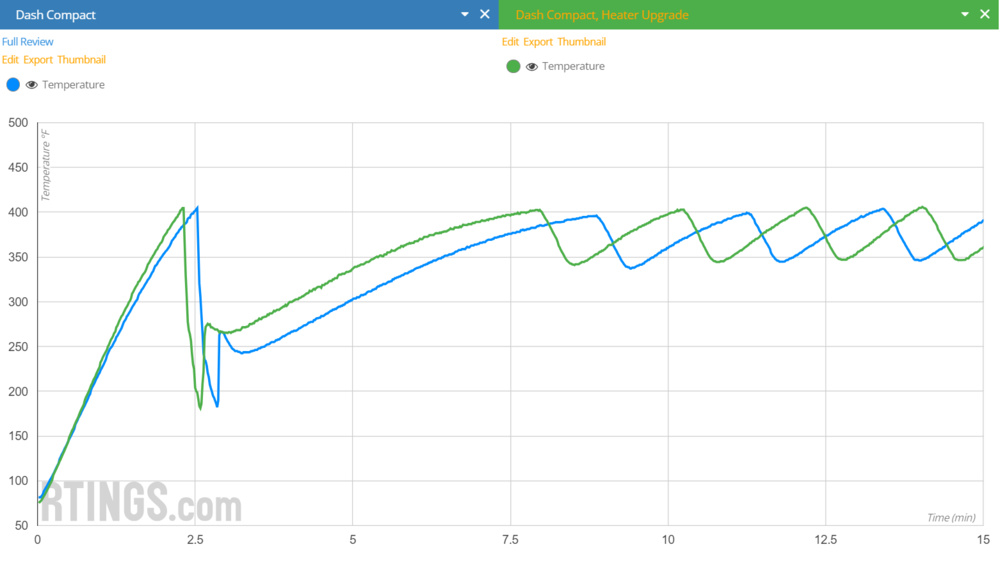

We kept the original motor speed and temperature control system to investigate the impact of increased wattage alone. Our tests show that the additional wattage improved the preheat time by 13 seconds and improved the recovery time by a significant 50 seconds.

In a cooking speed test, the prototype's additional wattage managed to cut off a full 5 minutes, reducing the time needed to hit our 45% moisture loss target from 28:53 to 23:52, a reduction of 17.4%.

More Airflow, More Heat Transfer

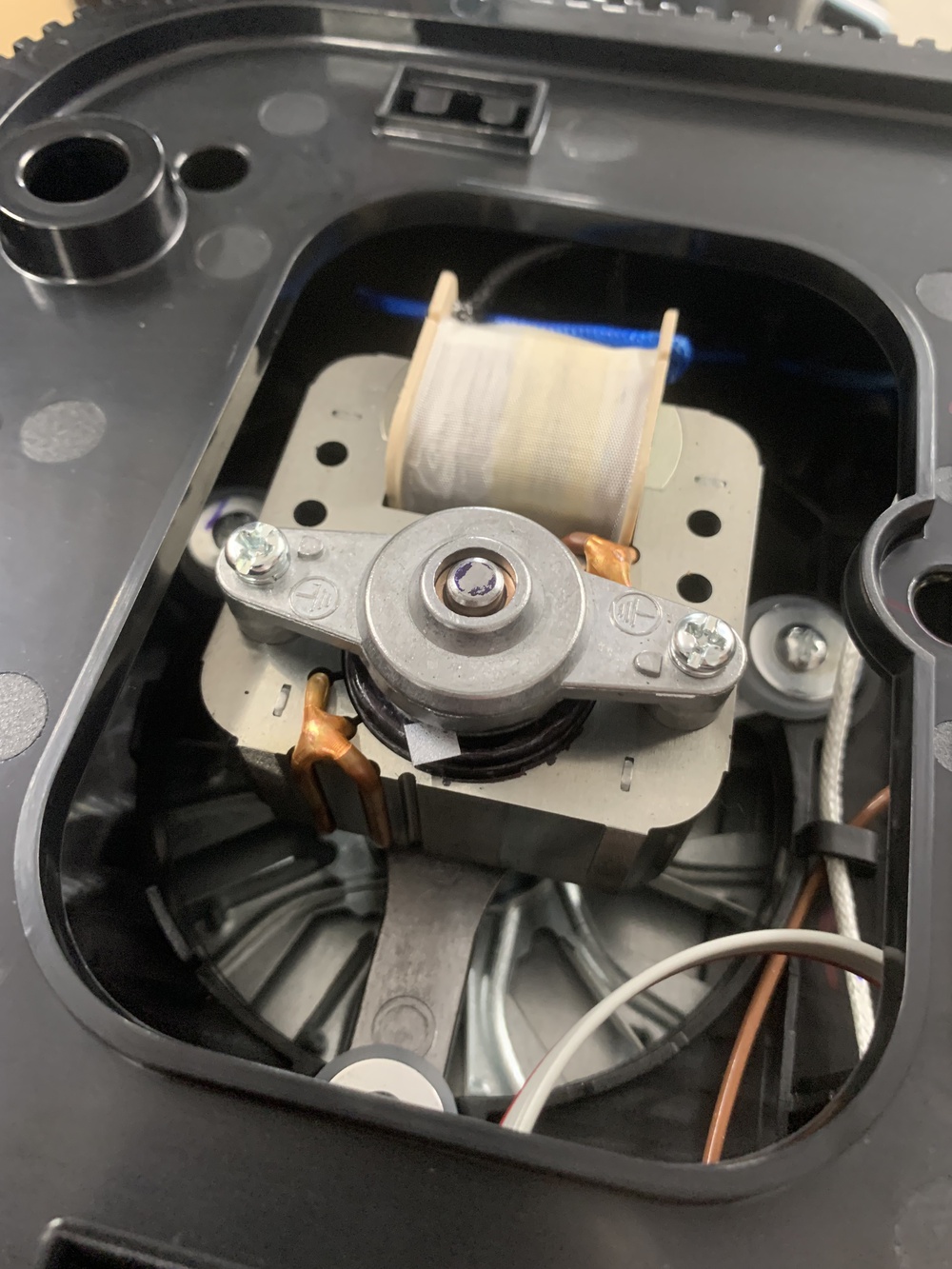

A higher wattage heating element significantly reduces cooking speed. The fan and motor in an air fryer are equally important to generate airflow and efficiently transfer heat to the food. The vast majority of air fryers employ a shaded-pole motor, a simple, low-cost, low-torque solution for generating airflow:

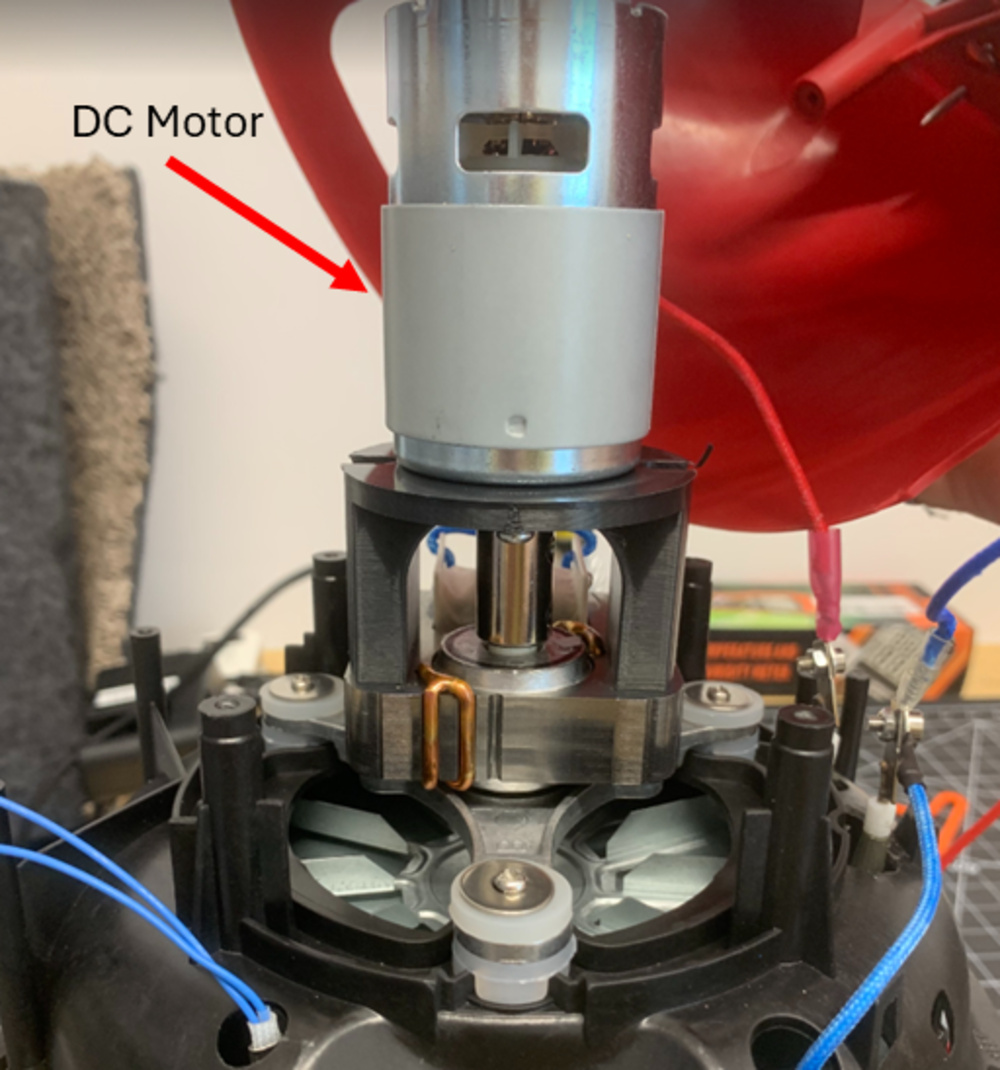

The limitation of such motors is that the frequency of alternating current determines their maximum speed. For example, our 60Hz electrical supply in North America means a theoretical maximum synchronous speed of 3600 RPM. However, in practice, air fryer fans typically spin at 2500-3100 RPM. As air fryer capacities increase, they use larger diameter fans to increase airflow. They range from as small as 3.35" (85 mm, as seen in the Dash Compact) to as large as 6" (152.4 mm) in air fryers with capacities of 6-8 quarts (5.68-7.57 liters). While bigger fans increase airflow in the chamber, they also impose a much greater load on the motor. Larger air fryers also accommodate more powerful motors to handle the increased load. Regardless of power versus load, this type of motor cannot exceed its synchronous speed of 3600 RPM. To be able to vary the fan speed and explore its effect, we coupled a high-powered DC motor and controller to our prototype:

It's important to note that higher speeds aren't always a good thing. In our testing, exceeding speeds of 4000 RPM began to lift and pull lightweight food into the fan, damaging both the food and the fan itself. Furthermore, increasing the speed without increasing the heater's available energy can lead to detrimental results. For example, with the original 1000 W heater, and by increasing the fan speed to 3300 RPM:

The preheat time increased to over five minutes, and after adding the food, the prototype couldn't recover its temperature even after ten minutes. While increasing the fan speed enhances the airflow past the heater and toward the food, it also increases both the exhaust rate and intake of fresh air. As a result, the heater remained on for the entire cycle (as the temperature never reached its set point of 400 °F), showing that the increase in airflow exceeded the system's capacity.

To take advantage of the added airflow, we increased the wattage again to 1300 W:

Graph of temperature over time showing the impact of greater fan speed and wattage versus the unmodified original

Graph of temperature over time showing the impact of greater fan speed and wattage versus the unmodified originalThe combination of the higher fan speed and wattage resulted in a 15-second decrease in preheat time and a 2-minute decrease in recovery time. With the heater and fan speed now effectively matched, and performing a cooking speed test:

This decreased the overall cooking time further to 22:14, a 6.8% decrease versus the increased wattage alone and a 23.0% decrease compared to the original Dash Compact. The increased airflow in the system allowed us to take full advantage of our additional wattage.

The Importance Of Temperature Control

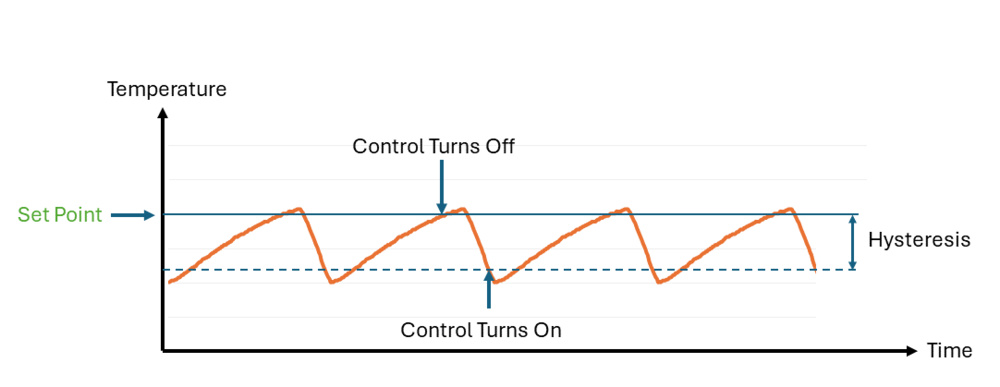

The temperature inside an air fryer's cooking chamber is controlled by monitoring the internal temperature and switching the heating element on or off. When the temperature exceeds the set temperature, the control system will switch off the heating element. When the temperature falls below a set limit, the system will switch the element on to bring the temperature back up. This range of temperatures is known as hysteresis:

A wide hysteresis means that once the set temperature has been reached, there will be a large period between each cycle in which the heating element is off and doesn't provide the additional energy required for cooking. These large fluctuations in temperature can lead to increased cooking times and make it difficult to achieve stable results in more sensitive processes like baking or dehydrating.

The Dash Compact employs a mechanical thermostat that senses the temperature based on the expansion of gas inside a bulb placed in the cooking chamber. It's a cost-effective solution, but its purely mechanical operation leads to a very wide hysteresis of 59 °F.

To fine-tune the control system in our prototype, we installed a thermistor and microcontroller, which are typical of most modern air fryers. We kept the original 1000W heater and 2900 RPM motor speed for this investigation. With the hysteresis value set to 20 °F, the temperature in the chamber fluctuated only by 27 °F:

By increasing the control system accuracy, the prototype achieved a cooking time of 25:06 versus 28:53 for the unmodified version, a decrease of 13.1%:

Leaving wattage and fan speed as they were, this highlights the importance of precise temperature control. Because the control system switched the heater back on at more regular intervals, significantly more energy was available for cooking, and the air fryer maintained a higher average temperature throughout the cooking cycle.

Optimizing Key Variables

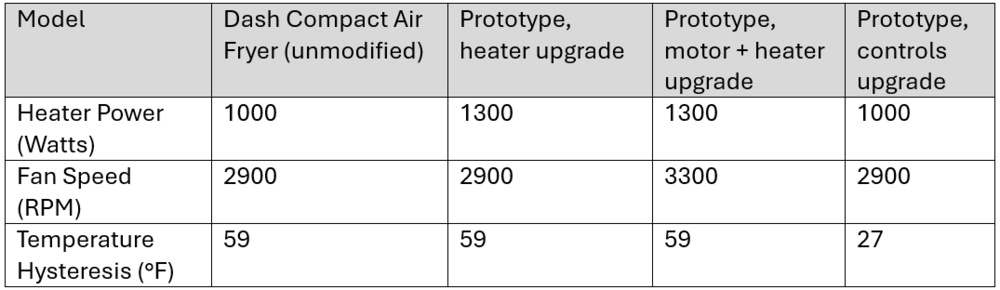

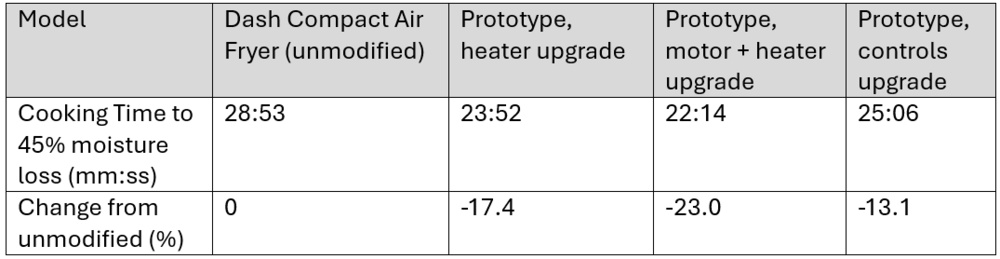

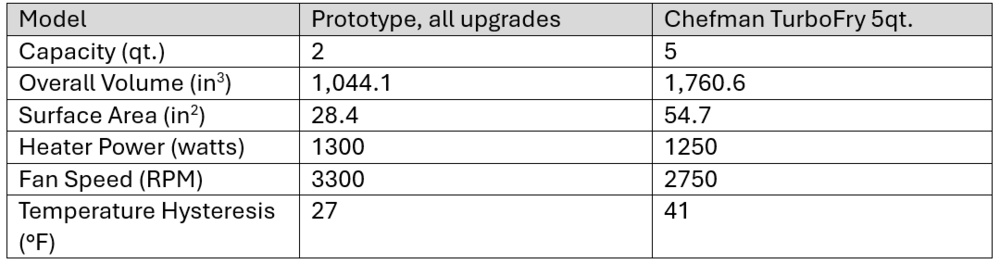

The table below is a recap of the individual modifications made to the prototype:

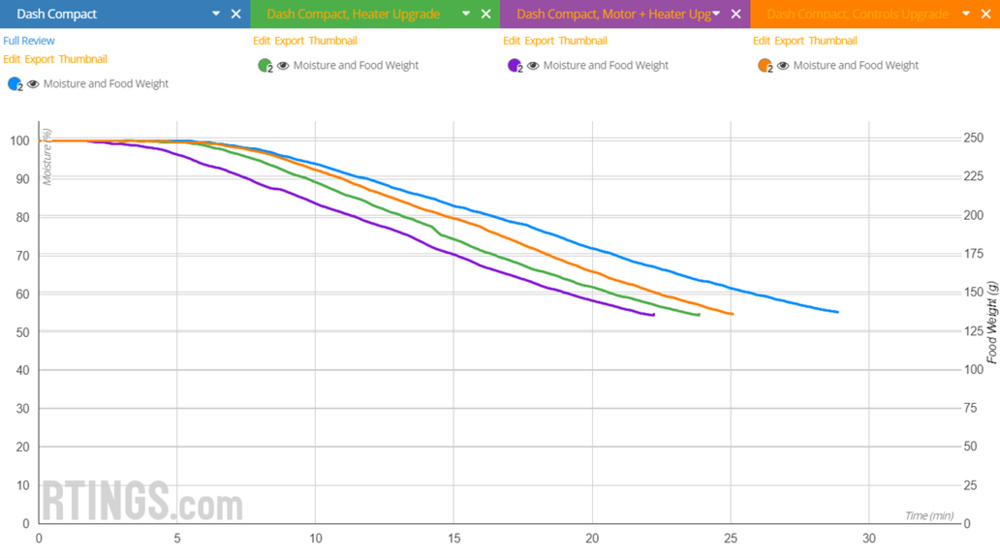

With all of the variables investigated on their own, the speed of each cooking test is plotted below:

The table below shows the performance impact of each modification. It's clear that increasing the heater wattage had the greatest impact alone while increasing the motor speed and resulting airflow let us maximize the effect of the increased wattage. Improving the system's responsiveness via reduced hysteresis alone also had a very significant impact.

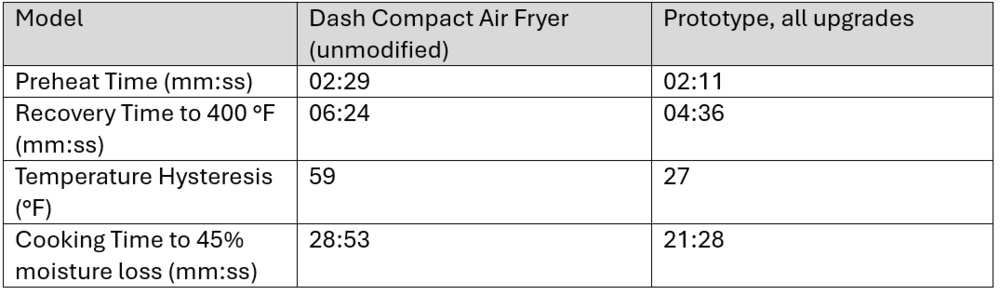

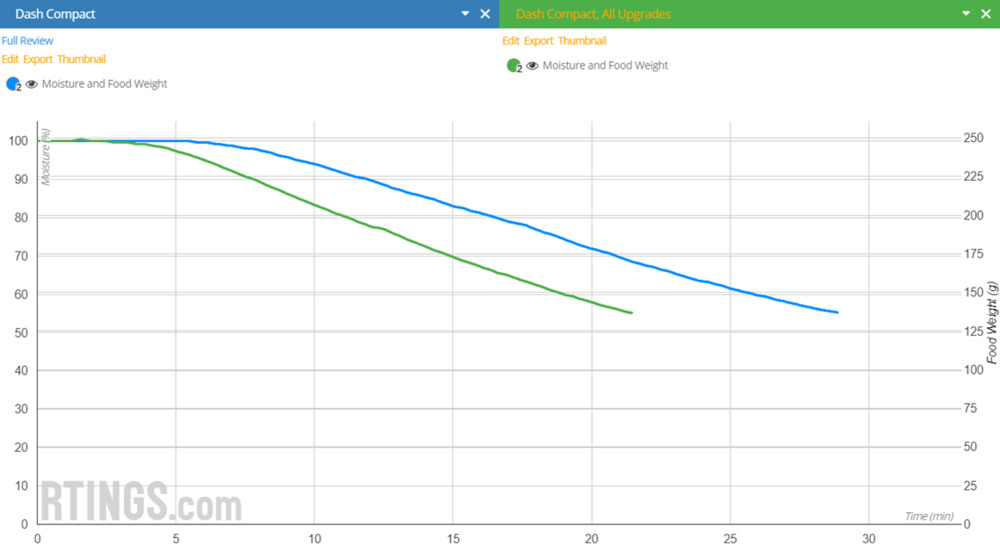

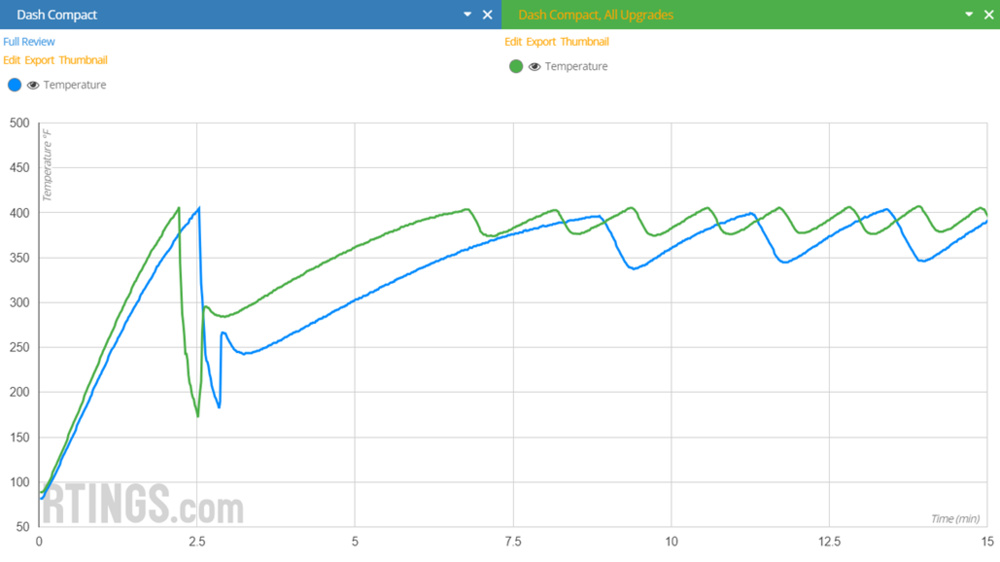

Combining all of the upgrades decreased the cooking time from 28:53 to 21:28, a 25.7% reduction. The resulting improvements in preheat speed, recovery time, temperature hysteresis, and, above all, cooking speed are clear.

Graph of temperature over time showing the impact of all upgrades combined versus the unmodified original

Graph of temperature over time showing the impact of all upgrades combined versus the unmodified originalFrom a scientific standpoint, the results are promising—we've created a faster and more stable air fryer. But how does it impact the end result—the food?

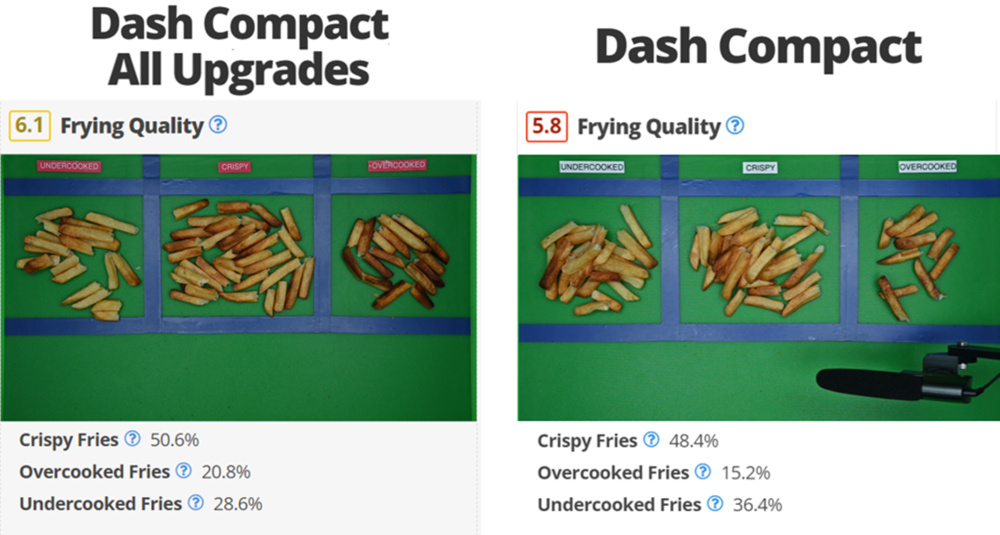

Despite improving several of the hard performance aspects of the Dash Compact, the air frying quality was only about 2% better by our metrics. While wattage, fan speed, and temperature control certainly make an impact, there was still the single most important factor we didn't change.

Cooking Chamber Design Should Maximize Surface Area

Compact air fryers with lower capacities seem attractive because they have a smaller countertop footprint and are easier to store when not in use. They're especially attractive if you only plan on cooking for one or two people. However, our testing concluded that even for small batches, bigger is better.

Not only do larger capacity air fryers house more powerful heaters and increased airflow (as previously discussed), but they also have one big advantage: surface area.

The Impact of Surface Area

In this sense, the surface area refers to the cooking tray's available area. A larger surface area allows you to cook more food placed in a single layer, so fewer food items overlap. This exposes more of the food directly to the heated air, significantly improving the cooking speed and, more importantly, the evenness and crispiness of the entire batch.

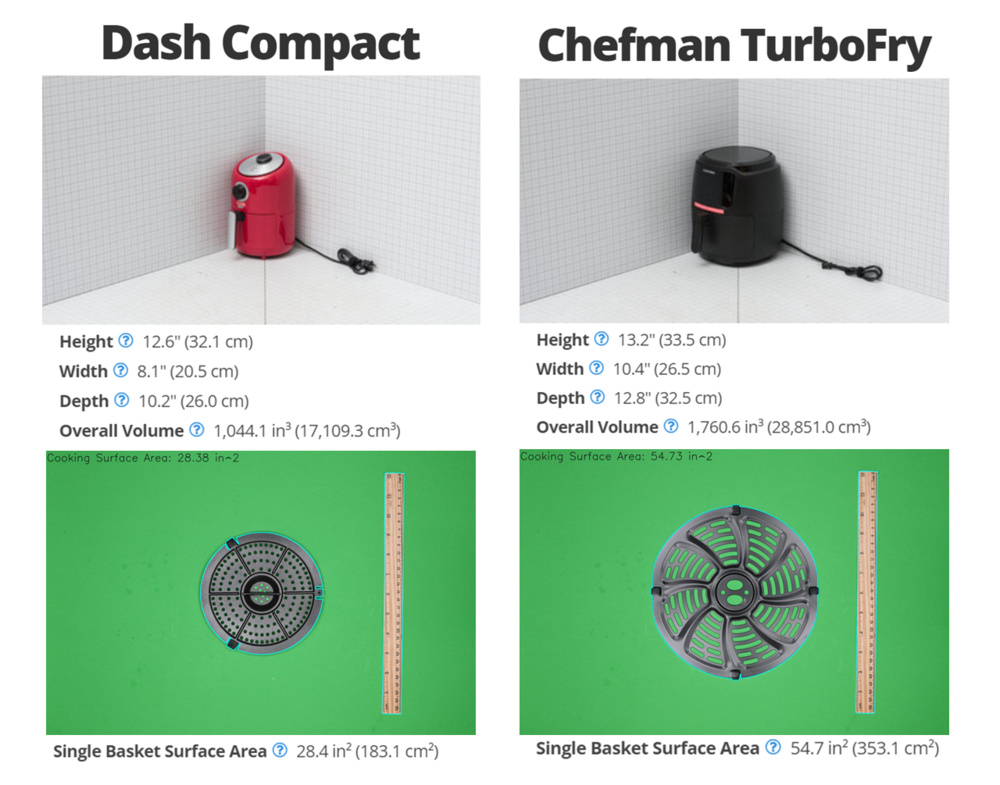

For comparison, take the Dash Compact and the Chefman TurboFry RJ38-5-T:

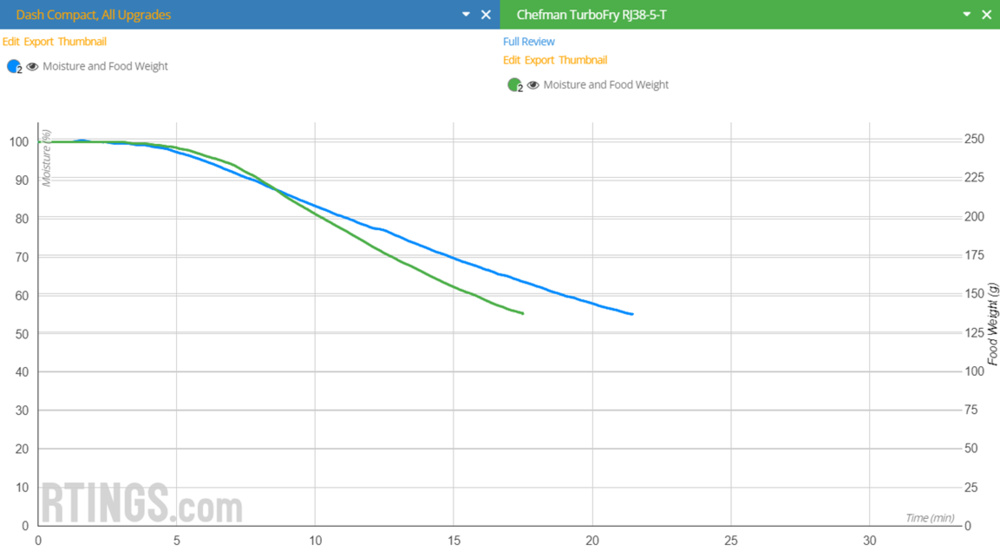

The Chefman TurboFry has 54.7 in2 of cooking surface area compared to that of 28.4 in2 in the Dash, an increase of 92%. Despite our prototype having slightly more power, a faster fan speed, and a more responsive control system, the TurboFry still pulls ahead:

It boasts a much-improved cooking time of 17:30, a decrease of 4 minutes from our prototype. It also scores significantly better in the frying quality test due to the greater surface area and improved air circulation in the larger chamber, ensuring more fries are cooked at the same rate and resulting in fewer fries in the under or overcooked extremes. It's important to note that neither of these air fryers was overloaded—the tests are run with the same 250g amount of fries, or about 35 fries, which is a reasonable serving size for 1-2 people.

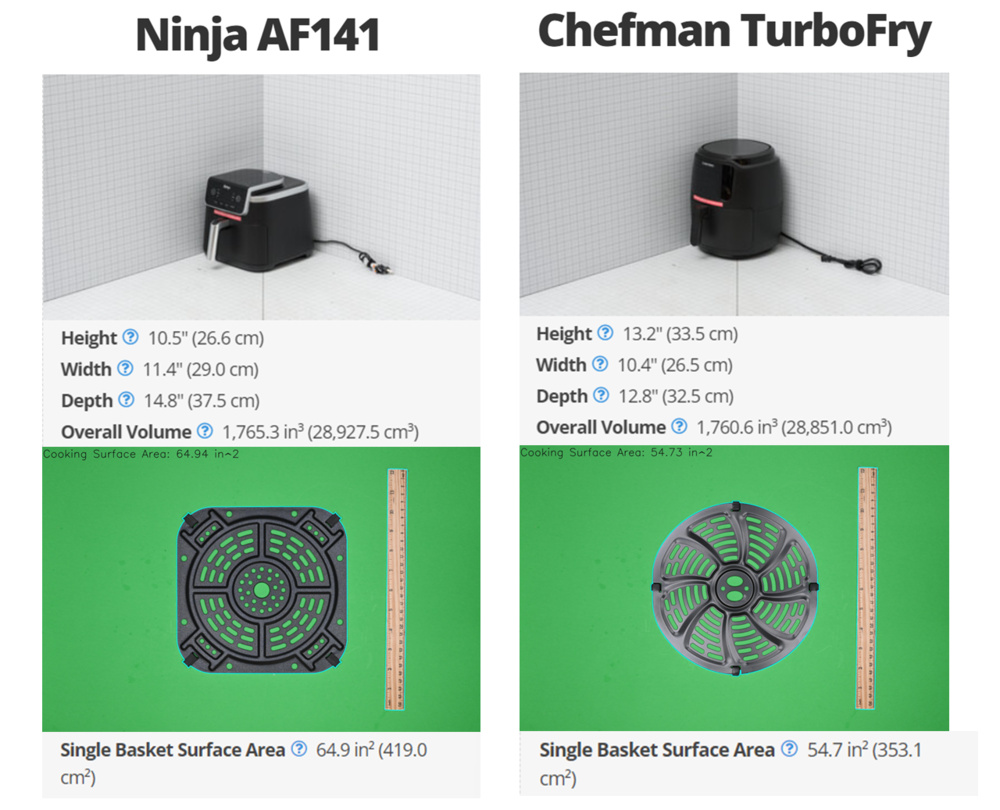

However, size or capacity alone does not always translate to a larger surface area. For example, the Ninja Pro AF141, with the same rated capacity of 5 quarts, has a larger surface area of 64.9in2, an increase of 18.6%, with the overall dimensions of the Ninja model being less than 1% larger than the TurboFry.

The COSORI TurboBlaze is an excellent example of high surface area to size ratio:

With an overall size of 1,958.1 in3, it’s only 10.9% larger than the already compact Ninja Pro AF141 while maintaining almost the same countertop footprint. Despite the similarity in size, it offers 16.2% more surface area, making it one of our top scorers in the frying quality test, with 81.2% of the fries being evenly cooked and crispy.

Toaster Ovens

Many modern toaster ovens now feature fans like those in air fryers, effectively making them compact, multifunctional convection ovens. Although they differ heavily in construction and layout, they offer many of the same components as air fryers—high-wattage heating elements, large fans, and extra-large cooking surface areas. Many models now feature a dedicated "Air Fry" function.

To assess their performance in air frying, we purchased a Cuisinart Air Fryer + Convection Toaster Oven (TOA-70):

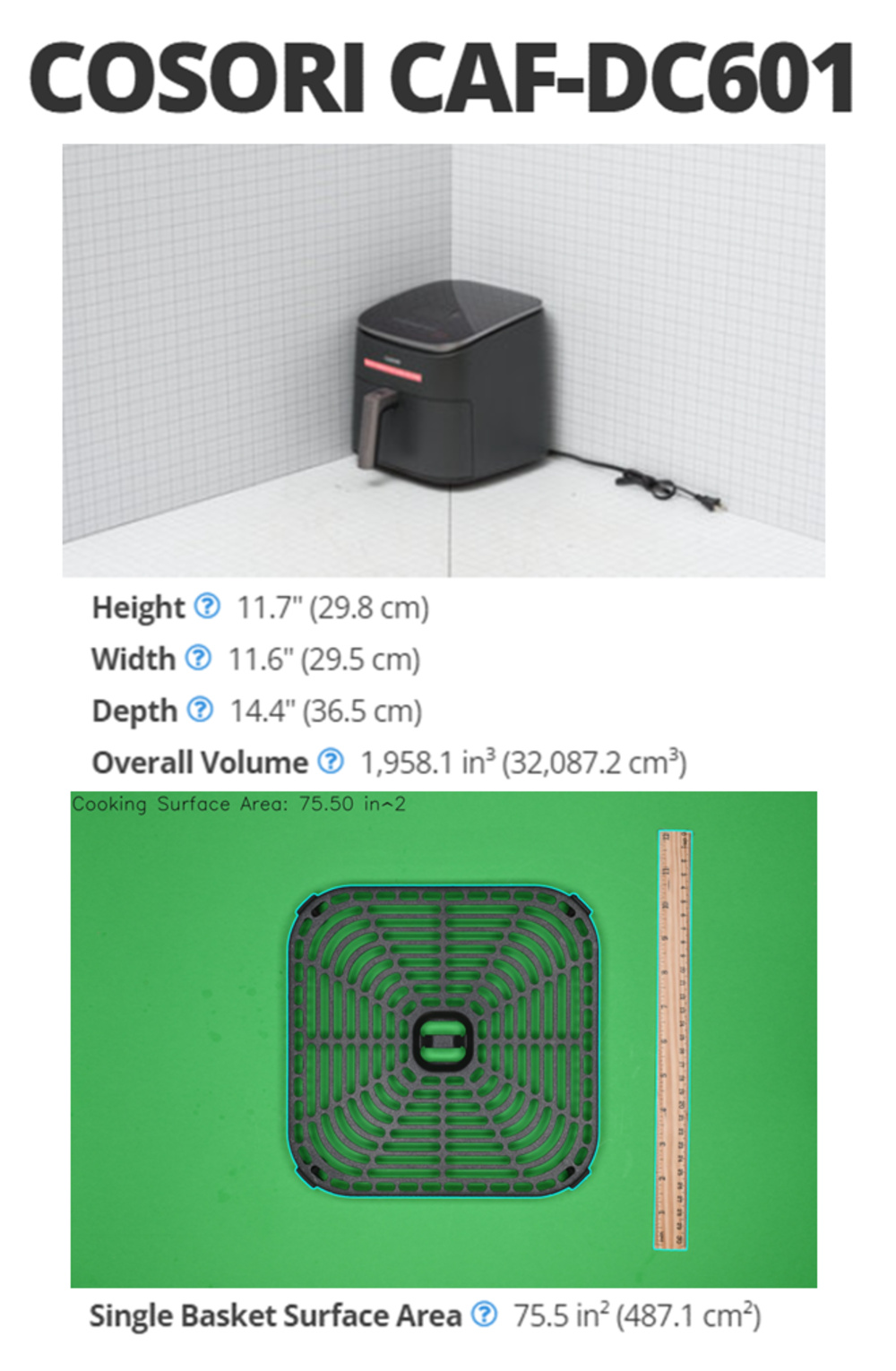

This particular oven offers an internal capacity of 0.6 ft3, or about 18 quarts (17 liters), larger than any air fryer we've tested, 1800 watts of heating power, and a large, top-mounted fan of 6" (152.4 mm) that spins at 2100 RPM, which provides airflow directly on top of the food. We ran it through the same panel of tests as our air fryers, starting with its impressive cooking surface area (using the provided mesh air fry basket):

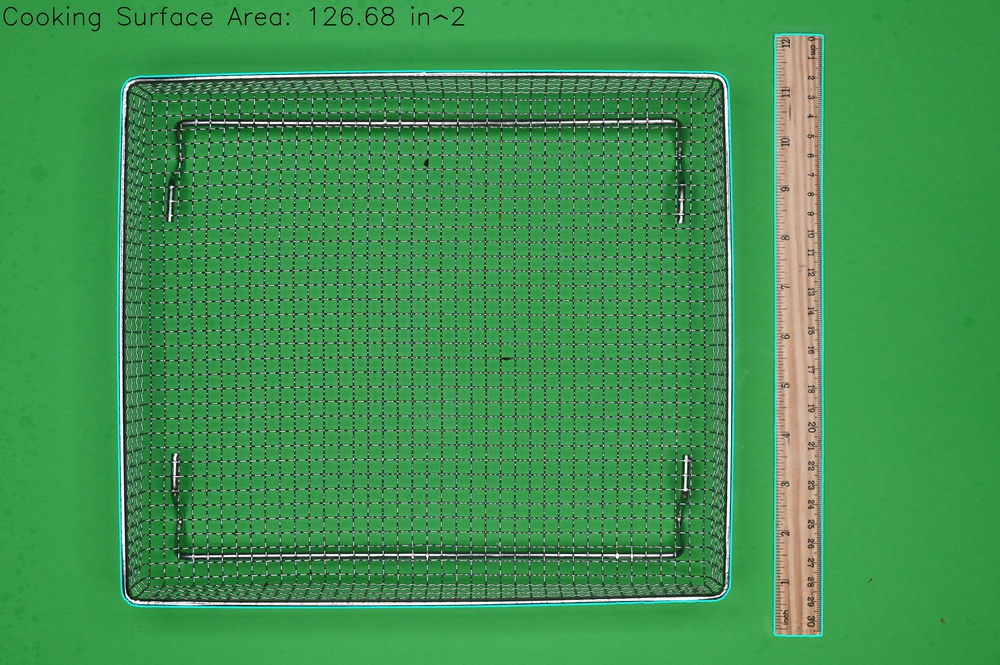

The basket’s cooking surface area of 126.7 in2 surpasses even the largest single basket air fryer we’ve tested (the Bella Pro Series 8 quart (7.57 liter). air fryer, with a surface area of 77.7 in2). For our first performance test, we tested the temperature stability of the oven:

Due to the large cooking chamber size, once the food was added following the preheat, it took a very long time of 05:48 to recover its temperature and had a temperature variation of 41 °F. The temperature recovery time isn't surprising given its high internal capacity (with similar power to a large air fryer). However, the temperature variation was better than that of some of the air fryers we tested.

Next up for performance was the standard cooking speed test with 250g of French fries:

The Cuisinart scored a very respectable cooking speed of 18:51, placing it right in the middle of the pack amongst our air fryers. This result was surprising given its high internal capacity and comparatively small fan. However, this oven features a well-insulated cooking chamber, with approximately a 0.5" air gap surrounding it on all sides between the chamber and outer housing. As for the frying quality:

The result was lackluster, given its very high cooking surface area. The large internal capacity should warrant a proportional increase in fan size, speed, and, most importantly, heating element wattage. However, as a countertop appliance, its available power is constrained by the amperage limit on standard North American outlets. The airflow is also spread out into a much larger cooking chamber, compared to an air fryer, which concentrates the airflow directly into a much smaller volume.

These results can likely be extrapolated into full-size, residential convection ovens, many of which also feature "Air Fry" modes. Despite massive increases in cooking chamber volume (and cooking surface area), the heating power and airflow are not scaled proportionally in this application. Simply put, air fryers pack a lot of power into a small package, making them faster, more efficient, and offering crispier results.

Two Baskets Doesn't Mean Twice The Speed

Naturally, dual-basket air fryers come to mind in discussions about surface area and air fryers. They offer extra-large capacities as high as 10 quarts (9.46 liters) and tout the ability to cook two batches of food in less time. Some air fryers (like the Ninja Foodi DZ071 and Beautiful 9QT TriZone) even feature a removable divider that allows the divided cooking chambers to combine into a single, high-capacity basket. One would reasonably think these devices are doing the work of two air fryers at once, reducing the cooking time—but this isn't the case.

Two Chambers, Two Heaters

Dual-basket air fryers, even those you can combine into a single cooking chamber, are more like two air fryers glued together. Each cooking chamber has its own full-wattage heater, fan, and temperature sensor. This means that only one heating element can be on at any given time (due to the current limits of breakers in North America). When cooking, the elements take turns providing heat to each chamber, successively increasing the temperature in each.

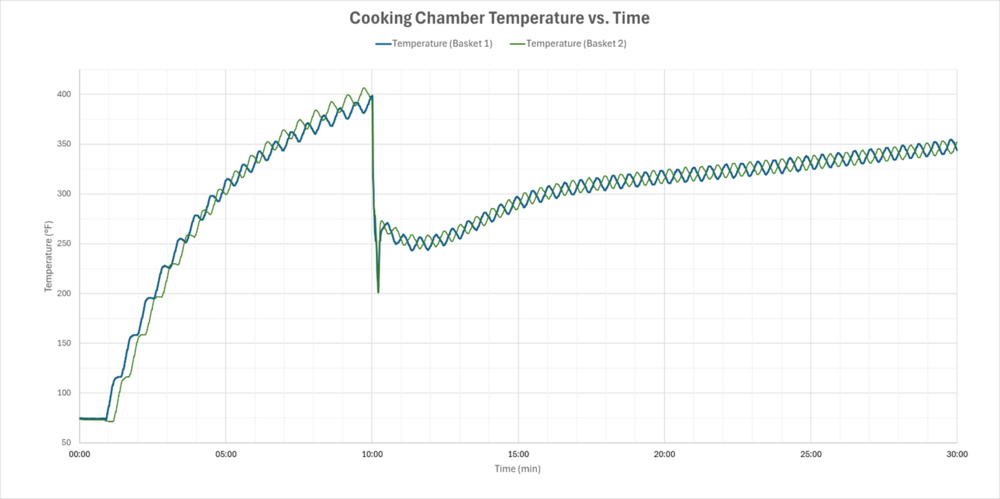

The graph below displays the temperature in each cooking chamber over a 30-minute cooking cycle. As only one heating element can be on at a time, it takes ten full minutes for both chambers to reach 400 °F, nearly four times the length it takes our longest air fryer to preheat. For the same reason, once food is added, neither chamber recovers to its set temperature of 400 °F over 30 minutes.

Graph of temperature over time in a dual basket air fryer, showing the temperature rise in each chamber as the heaters intermittently switch on and off

Graph of temperature over time in a dual basket air fryer, showing the temperature rise in each chamber as the heaters intermittently switch on and offIn practice, cooking time in each basket is greatly extended. When testing the Ninja Foodi DZ071, with double the amount of French fries split across each basket, it took a total of 31:00 to reach the 45% target moisture loss. Compared to the time it took to cook fries in a single basket (17:30), this is a 77.1% increase:

Conclusion

After evaluating the key inputs that contribute to the best air fryers, it's clear that larger capacity models offer significant advantages in speed, consistency, and cooking quality. While smaller models may be appealing for their compact size, they often fall short when delivering optimal performance. The increased surface area in larger air fryers allows for better airflow and more even cooking, resulting in crispier, more uniform outcomes.

Additionally, larger models' higher wattage and improved heat distribution lead to faster preheating and recovery times, ensuring that temperature remains stable throughout the cooking process. This results in more consistent cooking speeds and even doneness, regardless of portion size. Whether you're making a small meal or cooking for several people, larger-capacity air fryers tend to provide better overall results in a variety of cooking scenarios.