- Table of Contents

- Intro

- Note

- What's Changed?

- New Tests

- Let Us Know What You Think

- Completed Updates

- Comments

Test Bench 0.7

Changelog

See the previous 0.6 changelog.

See the next 0.8 changelog.

Note

This iteration of the robot vacuum test bench carries over from a time in which robot vacuums and conventional vacuums were tested with the same overall methodology. It corresponds to version 1.2 of the conventional vacuum test bench.

What's Changed?

With this iteration of the vacuum test bench, we added a new test to measure vacuum airflow and slightly updated our existing 'Suction' test. We've listed the changes made to our test methodology below.

| Test Group | Change |

| Airflow |

|

| Suction |

|

Here, we'll examine these new changes and how they can help you find the right vacuum for your needs. If you want to know more about our research and development process with this update—including investigations into the specifics of airflow measurement, the impact of airflow sensor placement, and how different vacuum types are expected to perform, you can check out our R&D article.

New Tests

Airflow

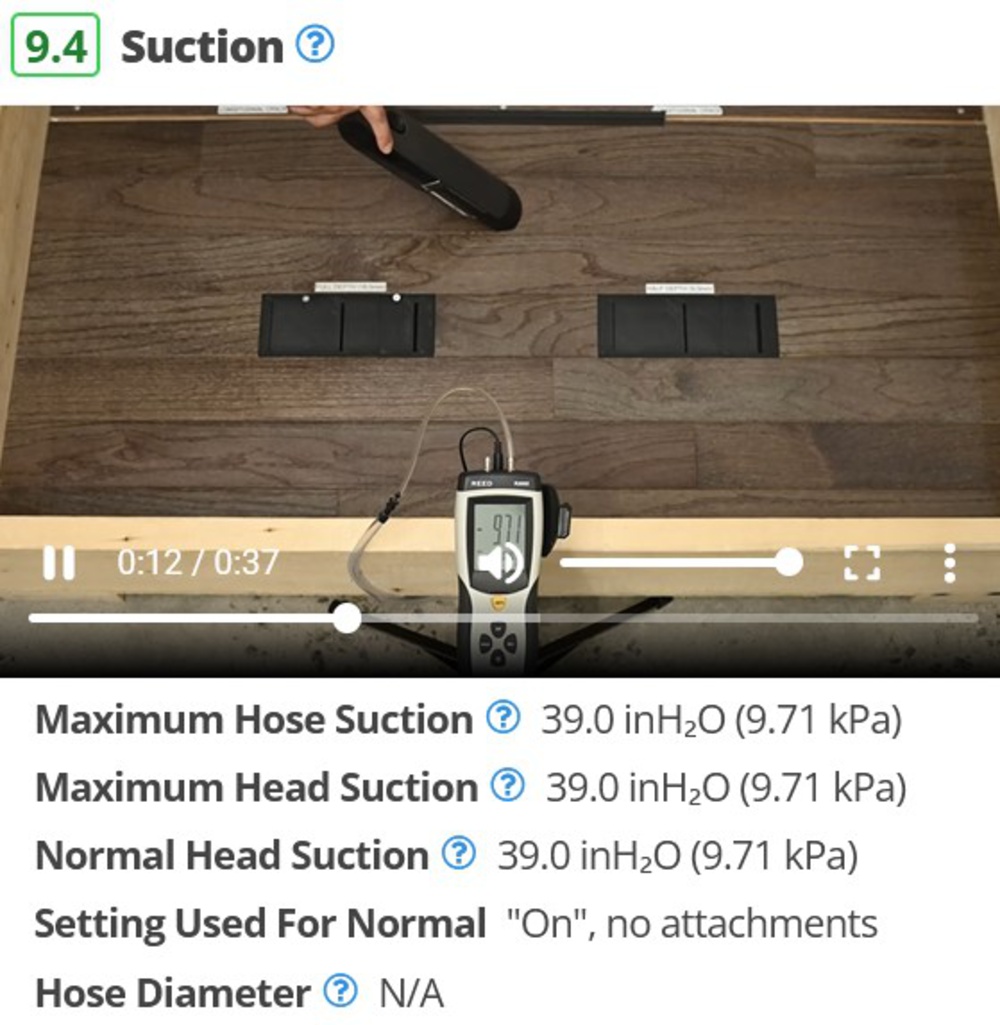

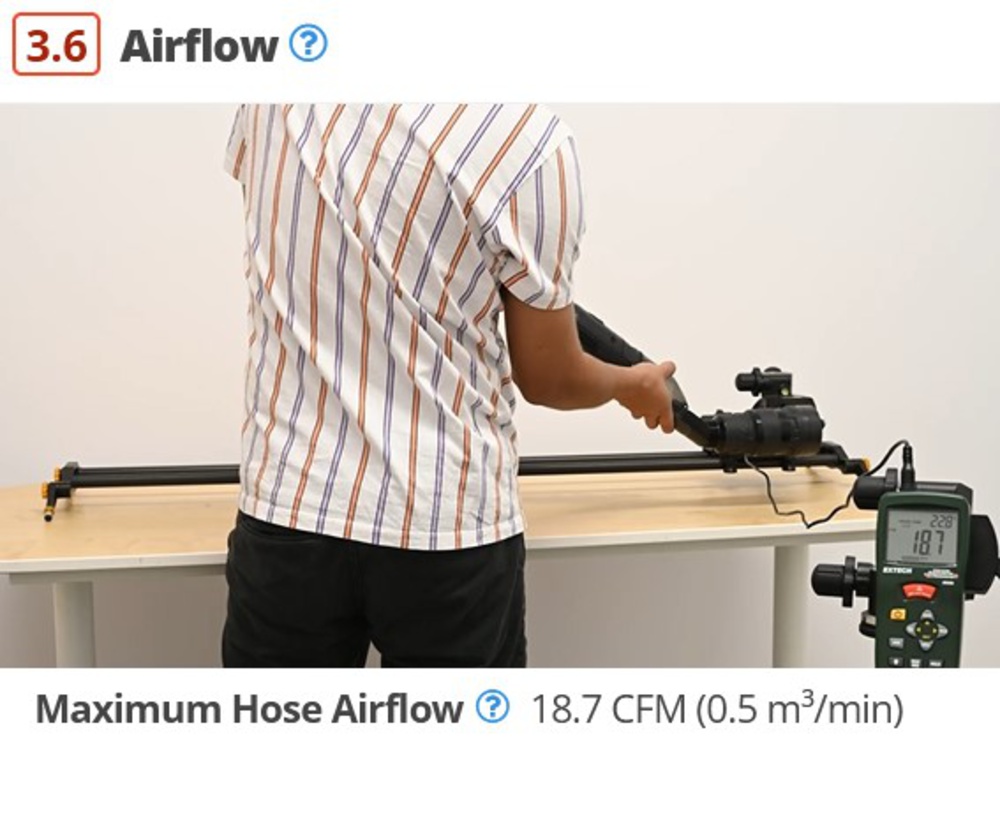

Here's an example of what the new 'Airflow' test looks like in one of our reviews.

The new box comprises a single element:

- Maximum Hose Airflow

Ultimately, this new test is self-explanatory, as it measures how much air a vacuum can move in its most powerful setting, using a customized anemometer and funnel arrangement to create a tight seal against the vacuum. It's an important supplement to our testing methodology, as it helps provide a far more comprehensive overview of system performance compared to measuring suction alone. After all, a vacuum can deliver superb suction but mediocre airflow performance; a clear example of why testing both elements is so important can be seen with a handheld vacuum like the Shark WANDVAC. The narrow suction inlet of this kind of vacuum would fully seal with the testing rig, resulting in a very high reading from our manometer. However, the actual volume of air moving through the system is very low, so naturally, debris pickup falls far behind a full-sized model.

It's worth noting that we test airflow differently for robot and non-robot vacuums. Since robovacs don't have a hose to measure from, they're set up on a different testing apparatus, being held aloft by foam padding, with an anemometer measuring airflow from their suction inlet. As such, the airflow measurements between robot and non-robot vacuums aren't directly comparable. If you'd like to read further into our reasoning and methodology for testing airflow differently on robot vacuums, refer to our R&D article.

Suction

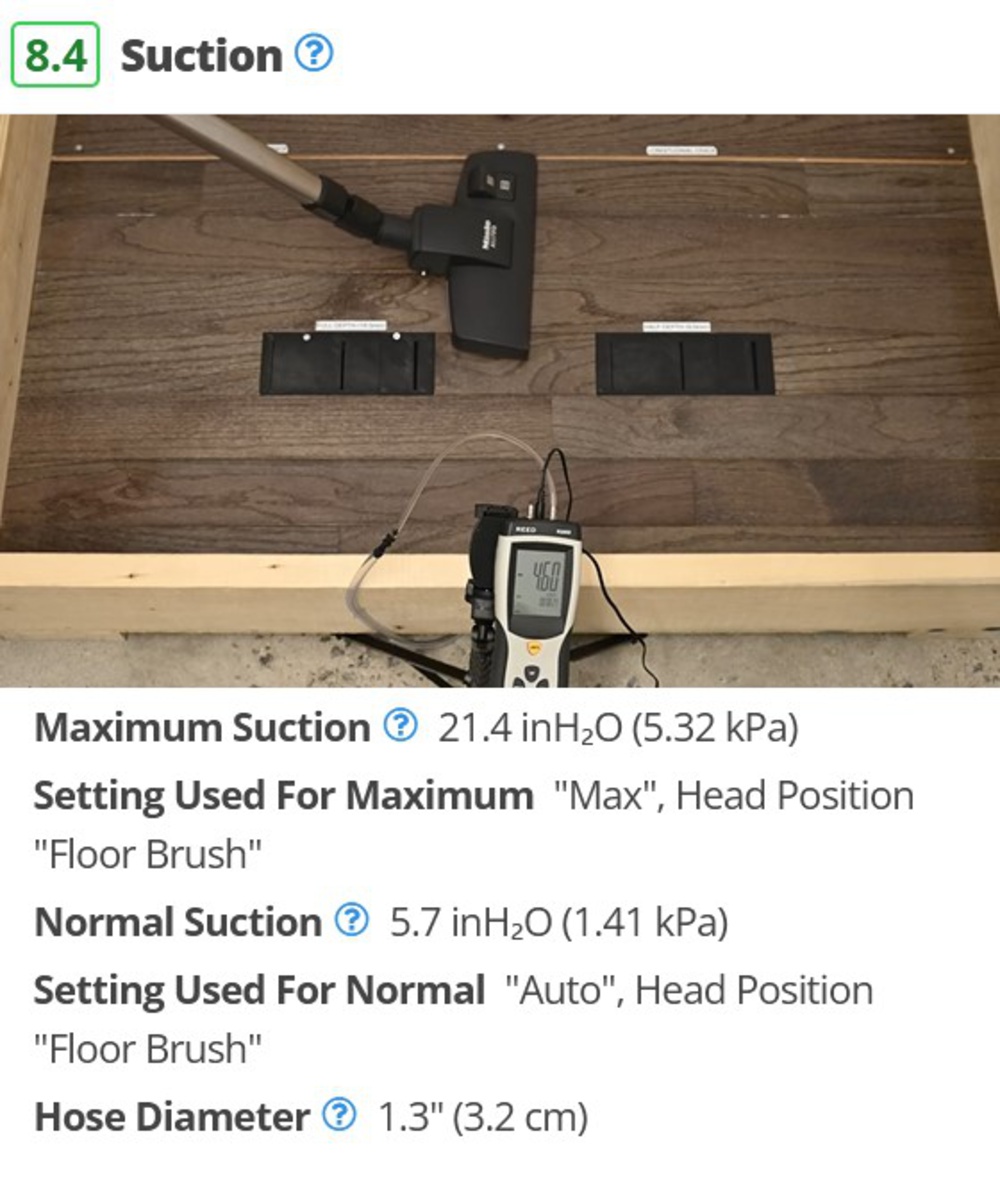

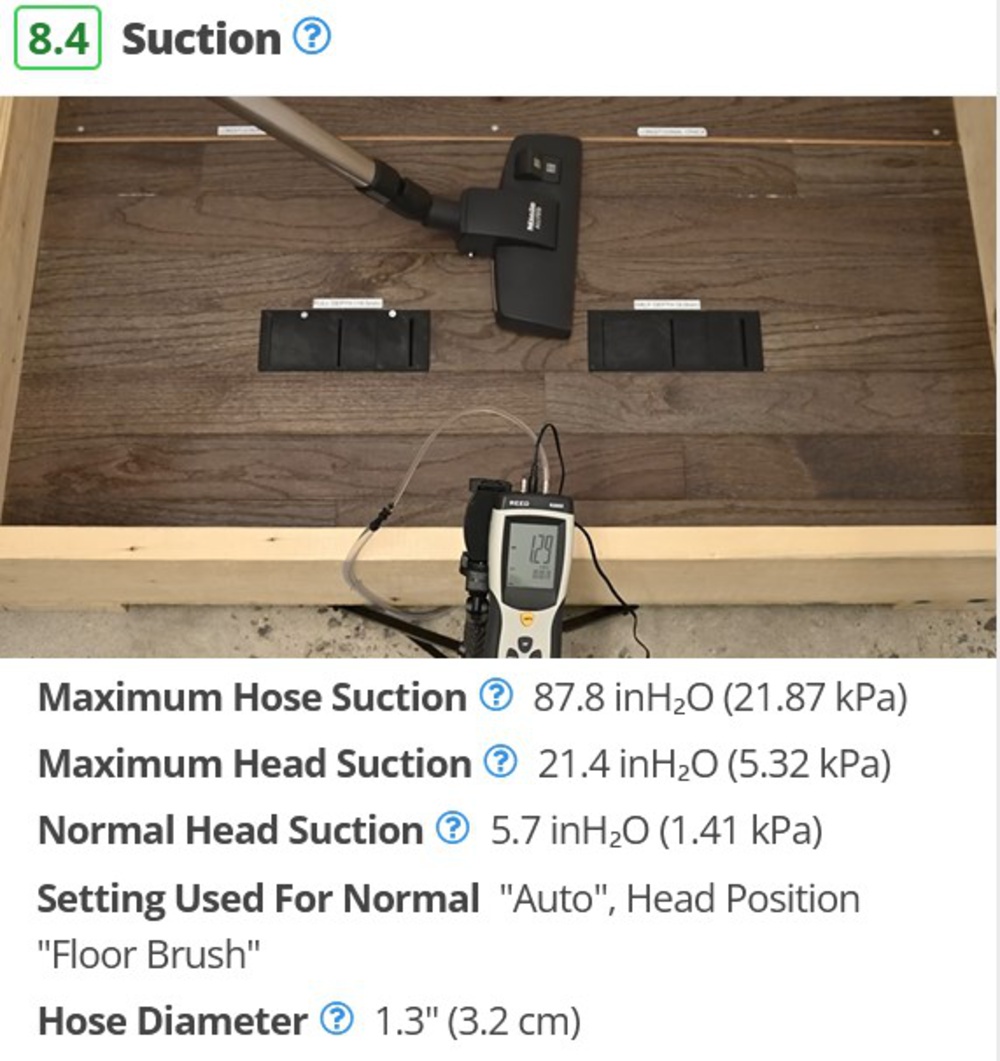

We've also updated our suction test to evaluate suction measured directly from the hose, as opposed to only the floorhead. Measuring suction from the hose paints a clearer picture of a vacuum's raw suction power than from measuring from the vacuum head. However, this obviously isn't as applicable to real-world usage. Here's a clear comparison between our previous and current iterations of the 'Suction' test.

Note that we've also renamed the ' Maximum Suction' test field to ' Maximum Head Suction' and the 'Normal Suction' test field to 'Normal Head Suction' to more clearly demonstrate where we're testing suction from.

Let Us Know What You Think

As always, our test methodology is a work in progress, and we depend on your feedback to improve it. Our methodology can always benefit from more meaningful tests. If you have comments, questions, or suggestions about this or any future updates, reach out to us in the forums.

37 Robot Vacuums Updated

We have retested popular models. The test results for the following models have been converted to the new testing methodology. However, the text might be inconsistent with the new results.

- Ecovacs DEEBOT OZMO T8 AIVI

- Neato D8

- Roborock E4

- Roborock Q5/Q5+

- Roborock Q7 Max+/Max

- Roborock S4 Max

- Roborock S5 Max

- Roborock S6

- Roborock S6 MaxV

- Roborock S7

- Roborock S7 MaxV

- Roborock S8+/S8

- Shark AI Robot

- Shark AI Ultra Robot [AV2501AE, AV2501S, AV2511AE, RV2502AE]

- Shark EZ Robot Self-Empty

- Shark ION Robot AV753 Series

- Shark ION Robot RV700 Series [RV750, RV761]

- Shark IQ 2-in-1 [RV2410WD, UR2410WD]

- Shark IQ Robot

- Shark Matrix Robot [RV2300S, RV2310AE]

- Wyze Robot Vacuum

- eufy RoboVac 25C

- eufy RoboVac G20

- eufy RoboVac G30

- eufy RoboVac X8

- iRobot Roomba 694 [690, 692]

- iRobot Roomba 981

- iRobot Roomba E5

- iRobot Roomba S9

- iRobot Roomba i1

- iRobot Roomba i3

- iRobot Roomba i4

- iRobot Roomba i7

- iRobot Roomba i8+

- iRobot Roomba j7/j7+

- yeedi K650

- yeedi vac station

Comments

Test Bench: Airflow: Main Discussion

What do you think of our article? Let us know below.

Want to learn more? Check out our complete list of articles and tests on the R&D page.